Table of Contents

<a href="?do=export_pdf">Printable PDF</a>

04SolderingSolarCells

Overview

This lesson will teach students specific techniques for soldering to solar panels, and give them the chance to solder together and finish their panels. The students first practice on bare wires, then move on to the more delicate task of soldering solar cells. Instructors should have practiced soldering to solar cells ahead of time – if you've soldered before, you should pick it up quickly, but it's good to have done it once or twice before showing other people.

Materials

- Solar cell pieces (from Lesson 3)

- Wire - preferably uninsulated tinned copper wire. Some pieces of scrap wire for practicing soldering if class has not done it before.

- Cardboard or similar for backing panels

- Clear material for covering panels - plastic, plexiglass, glass

- Tape, glue, nails, thumbtacks, etc. for attaching things - double sided foam tape works well on cells

- Scissors or knife

- Wire cutters

- Wire strippers are also useful if wire is insulated

- Solder

- Soldering iron - preferably 1/every 2 students

Background Concepts

If students haven't soldered at all before, you'll need to show them how to do it in the general sense before learning the specifics of soldering solar cells. The 'how to solder' comic in the 'Background Information' section of the main book is a good set of general soldering instructions. You can practice by twisting the leads of two parts, or a part and some wire, together and then soldering that joint.

REMEMBER SOLDERING IRONS ARE HOT. DON'T LET THEM SIT ON FLAMMABLE THINGS! DON'T TOUCH THEM WHILE ON OR RECENTLY ON! HAVE A WATER SOURCE NEARBY IN CASE OF ACCIDENT.

How to Solder to Solar cells

- Since the front contacts are white, they don't hold heat very well. It is the metal being heated that allows the solder to flow onto it. Cells are also damaged by excessive exposure to high heat. So, we're going to do this a little differently to ordinary wire soldering.

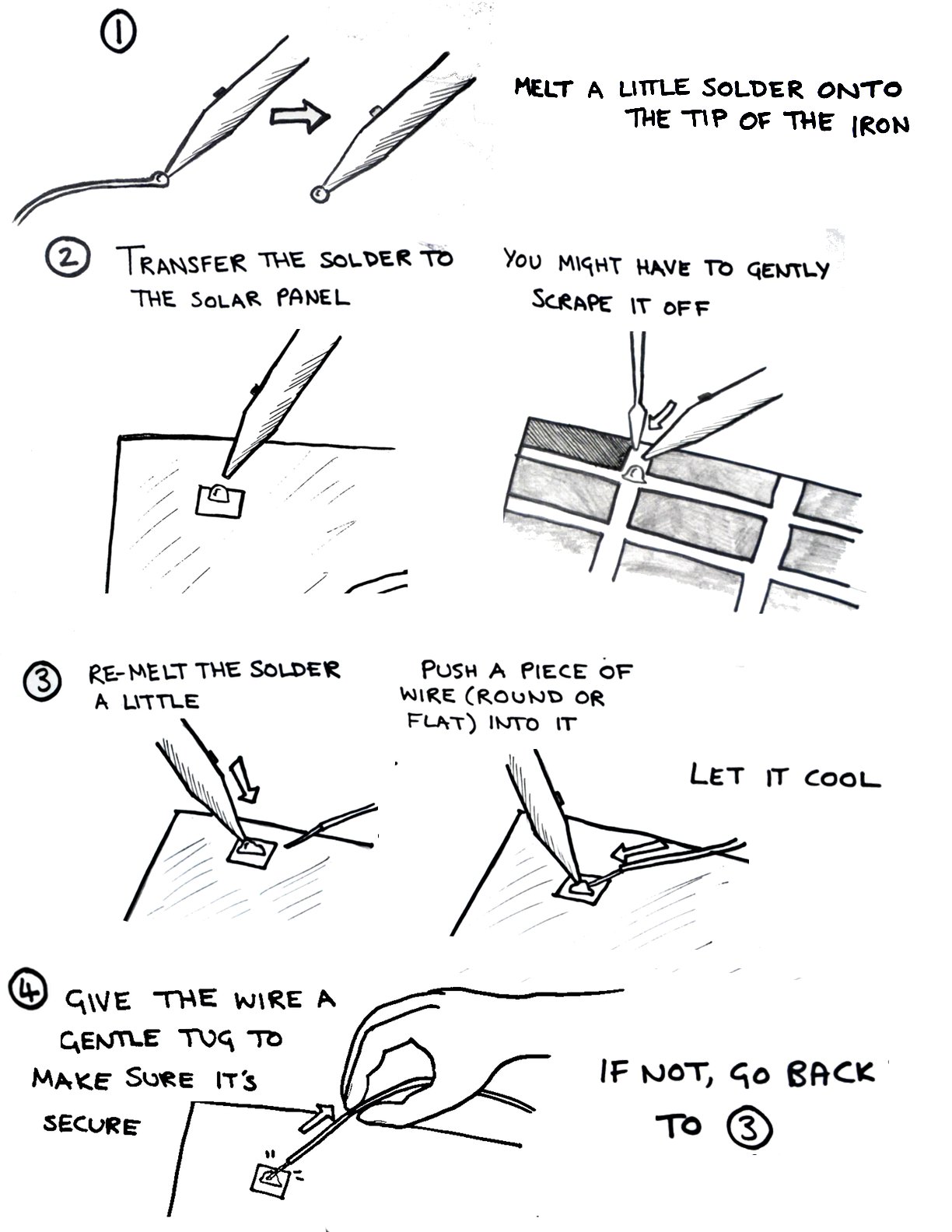

- Put some solder on the soldering iron tip. Do this not over the cell - if it splatters onto the cell face it would damage it. You should then be able to transfer the solder to the cell, by holding the iron with solder against the cell for a few seconds and then, if needed, scraping the solder off onto the cell contact.

- Reheat the solder by putting the iron on top of it, and push a prepared piece of wire into the melted blob.

- Remove the iron and let the joint cool. Test it. If the wire isn't secure, heat it again and poke it a little further in.

Lesson Plan

1. DEMO & SAFETY

Have students soldered before? If so, great. If not, demonstrate how to solder (an LED to a resistor might be something to start with that they can use later) and have each student make at least one good solder joint. Remind students about soldering iron safety.

2. CLASS DISCUSSION

Ask class to remember how to connect solar cells – the front of one cell should be connected to the back of the next and so on. What should the ends of the string of cells look like? One should have a fairly long (8-16 inches probably works well) wire(s) coming off the front, the other off the back. The one where the wires are coming from the back should have its front connected to the next cell's back, and the end with wires coming off the front should have its back connected to the previous cell's front. Why are we connecting them like this? So the electrons flow through all the cells, and the voltage adds.

3. SOLDERING CELLS

Have each student try soldering one or two wires onto solar cells. Give pointers and guide hands if necessary. Working in pairs can be great, because someone can hold down panel pieces while another student solders to them (just be sure to keep fingers out of the way of the hot iron). Two students working like this can finish both their panels more quickly than if each had their own iron. Have students finish soldering panels. It can work best if once two cells are connected they leave them face up, solder wires to the backs of each new cell, turn these over, and attach face up to the string. Then you aren't trying to flip an ever-growing network of delicate cells back and forth. With tips like these, give the students time to figure it out on their own, then make suggestions if they have problems.

4. FINISHING THE PANELS

Once the panels are soldered together, finish the panels as discussed at the end of lesson 2 (mounting on cardboard or something similar, covering to protect cells from dirt and grime).

5. TEST THE PANELS

Test panels with multi-meters to show they produce as much voltage (and current) as predicted.